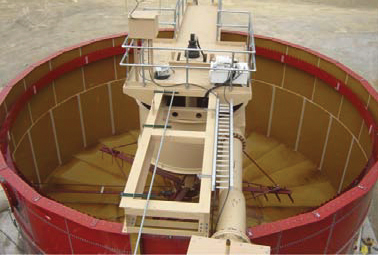

McLanahan High Rate Thickener

High-Rate Thickeners, or Clarifiers, recover immediately reusable process water for mineral and aggregate producers, as well as environmental contractors. Thickeners are beneficial in a variety of applications, including areas where water is in short supply or very expensive, re-circulated water is not suitable for reuse in a plant, ponds are located on minable reserves, or ponds must be reduced in size due to permitting issues.

High-Rate Thickeners provide immediately reuseable process water and recover approximately 85% of the water from an effluent feed. This high level of water recovery keeps water consumption at sustainable levels, as well as drastically reduces the slurry volume reporting to the tailings dam.

UltraCLEAR range comprises:

HRT10 – 10m Dia

HRT12 – 12m Dia

HRT15 – 15m Dia

Integration of McLanahan High-Rate Thickeners into a plant is simple. Control systems take care of most of the operation; however, McLanahan can train operators in the preparation and use of flocculants, as well as general Thickener operation.

How It Works

High-Rate Thickeners separate liquids from solids using hindered settling. Rotating rake arms collect settled sludge and move it toward the centre discharge cone. They use minimal amounts of polymers/chemicals to drop the solids, making High-Rate Thickeners environmentally friendly.

Thickeners are operated and controlled by a touch-screen programmable logic controller system. Operating logic allows for customization of the unit for plant needs, including the ability for the Thickener to shut down without an operator being present during extended hours of operation. The hydraulic drive gives an accurate sense of torque on the rakes. At high torque conditions, a rake lift will activate to draw the rakes up from the mud. The system then steps the rake down, monitoring torque on the way.