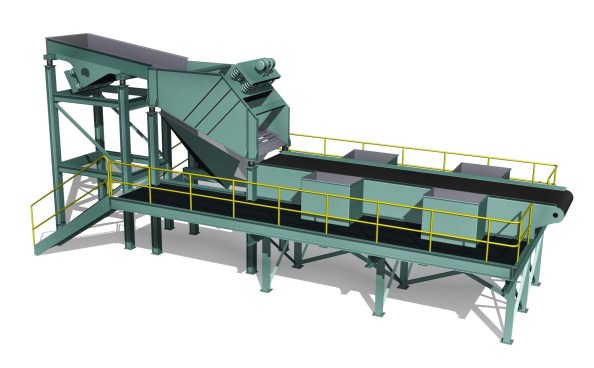

Action DENSE-OUT® Vibratory AIR Separator

The DENSE-OUT® is a cost-effective density separation solution for bulk processing of a wide range of materials fully capable of removing heavy materials such as rocks, bricks, metals, glass, ice lumps and knots from less dense materials.

The ideal combination of form and function. Action’s versatile, multi-stage, vibratory density separator integrates the advantages of vibratory technology with controlled air for the efficient separation of a wide range of mixed materials.

Features & benefits:

- The use of air as a separation medium in conjunction with core vibratory technology conveys and fluidizes materials for accurate, high capacity separations

- Recover the highest quality and quantity of end products

- Compact design for easy integration

- Dry system. No water storage, settling tanks, sludge generation or product degradation

- Rugged construction for reliable 24-hour industrial use

- Efficient air and energy usage

- Adjustability provides flexibility for greater separation efficiency

- Reduces manual labour and maintenance costs

- Reduces landfill volumes and disposal fees

- Can be retrofitted within an existing plant

- Operation is based on a simple yet precise blowing principle rather than an energy-intensive, complex suction arrangement