Lincom Group takes pride in creating lasting partnerships with its valued customers.

The best business partnerships are the ones that evolve into a genuine friendship.

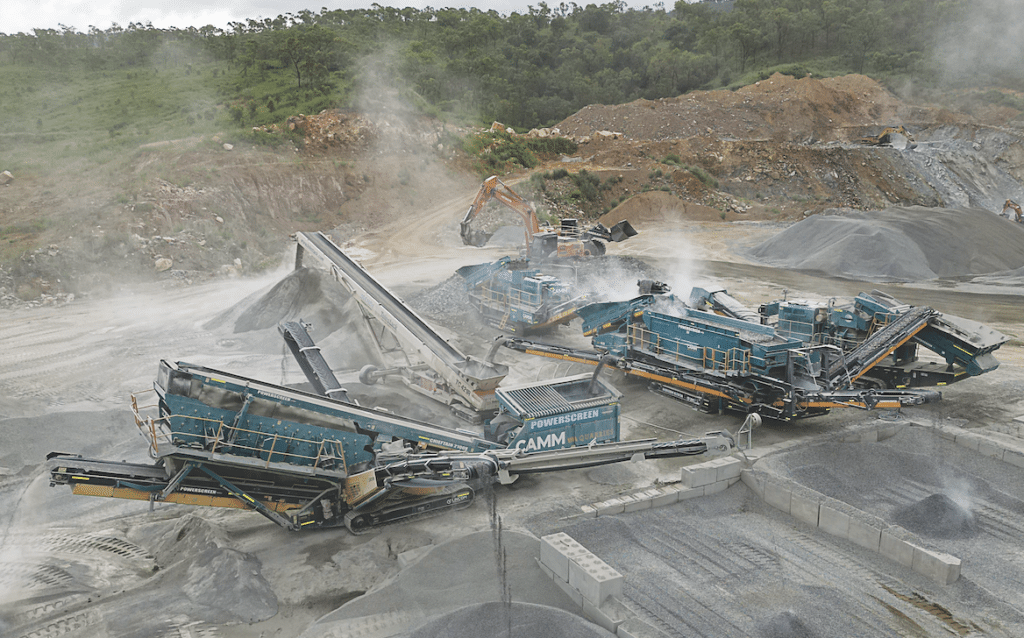

Such is the case for Lincom Group and Doyle Group’s CAMM Quarries business, companies that have been working together to deliver the ultimate in crushing and screening production for the past 25 years.

So when CAMM needed to increase production and efficiency across its North Queensland operation, the company knew to turn to Lincom to get the job done.

“CAMM needed equipment that was capable of producing higher tonnes per hour,” Lincom area sales manager – North Queensland and PNG Erwin Koch told Australian Mining. “But they wanted to be able to expand their production without going back to the drawing board while also bringing down cost of tonne per hour.”

While other companies may have balked at the task, Lincom took it in stride.

First, Lincom sat down with CAMM to discuss and understand the needs and expected outcomes of the quarry.

Once that was in place, it was time to develop aggregate flow charts to provide theoretical production rates and yields. Then, the upgrades began.

Lincom worked to upgrade the primary jaw crusher on site from the PT400X to the PT600PS; the 1000 Maxtrak cone crushers to the 1300 Maxtrack; and the screening equipment from the Chieftain style to the H6203R.

CAMM Quarries managing director Jeffrey Doyle was thrilled with the final result.

“With the guidance of Lincom and Powerscreen, we decided that with the introduction of new and larger equipment we could crush more tonnes per hour which consequently reduced our need to crush as long,” Doyle said.

“These efficiencies have allowed us to ensure better utilisation of personnel and machinery and increased planned maintenance to decrease downtime and reduce unplanned issues.”

With the upgraded equipment, the quarry was able to achieve a production rate of 220 tonnes per hour – a 70 per cent increase.

“Consistent reliability and production have been sorted by this modification,” Doyle said. “The aggregate plant may run for three eight-hour days per week rather than the six 10-hour days previously.”

For Koch, a major highlight from the project was working closely with a company that has become more like family.

“CAMM put a lot of trust in Lincom for this project, and we worked together to plan the achievements,” he said.

“Lincom’s values align closely with CAMM’s values, and that one inquiry 25 years ago has turned a customer into a family friend. We even have Christmas parties together.”

Turning customers into long-term friends and partners is the bread and butter of Lincom operations because the machinery isn’t forgotten about as soon as it reaches site.

“We need to have ongoing conversations about the machinery,” Koch said. “We don’t just deliver it and then forget it’s there.

“The after-sales support is just as important as the before-sales support. And we get a real kick out of seeing the machines work for our customers and hearing stories about what they have been able to achieve with them.”

For both Lincom and CAMM Quarries, trust isn’t just a word; it’s an ethos that has seen both companies thrive.

“There’s nothing better than helping people achieve their goals,” Koch said. “Watching a client go from an inquiry to a customer to a part of the family never gets old, but you need strong trust in each other to get to that point.”

For CAMM Quarries, which is now regularly achieving a boost in production and a reduction in cost of tonne per hour, the investment in Lincom has been a big success.

“We continually monitor our hourly throughput to ensure feed rates are maintained and machines are running at the optimum,” Doyle said.

“Hourly rates are tracked and communicated to supervisors and plant operators; you would be surprised of the difference this can make in a day.”

This article was published in the February issue of the Australian Minning magazine.